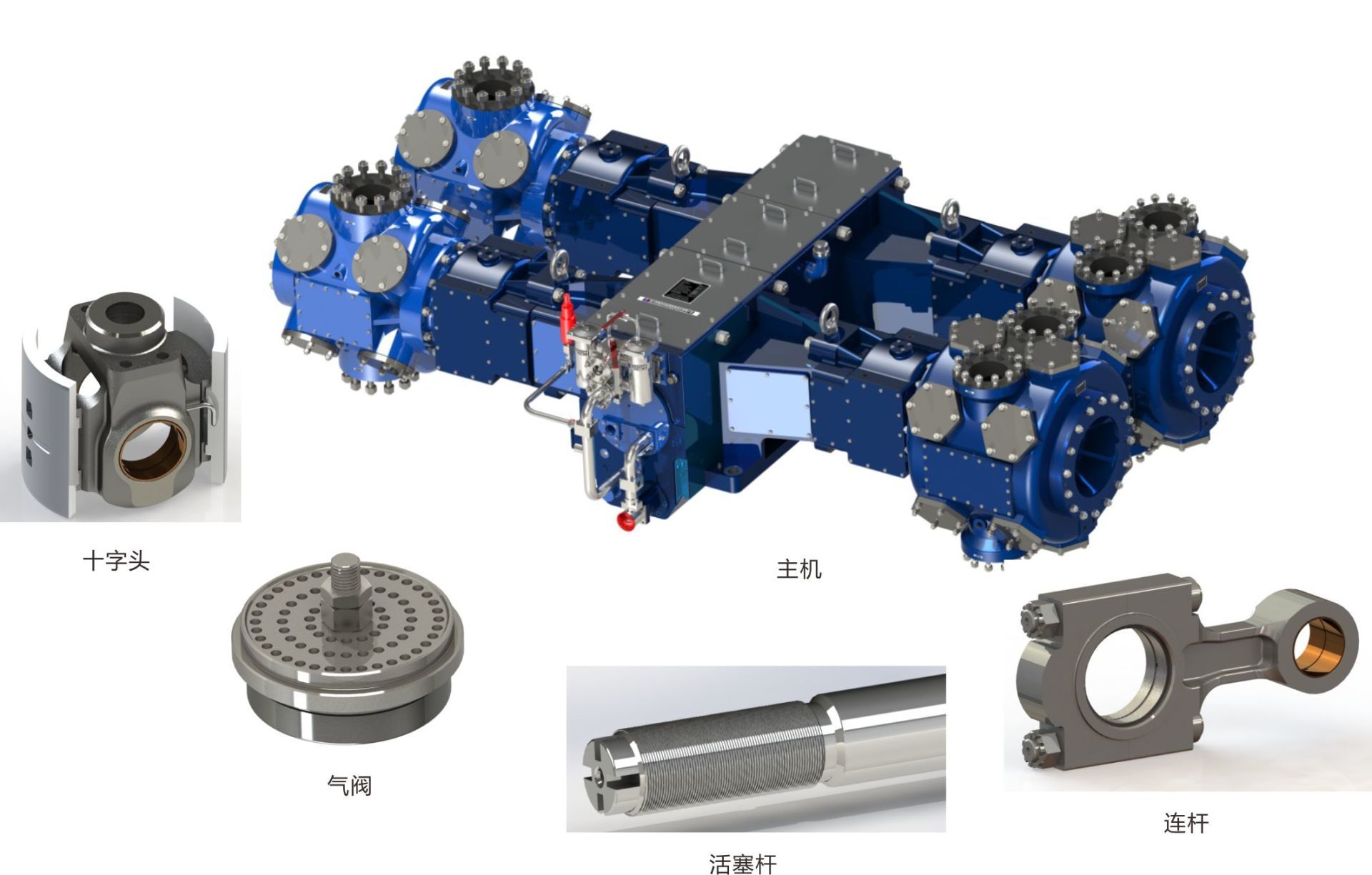

Venus series large high speed reciprocating compressor

Key words:

Venus series large high speed reciprocating compressor

Classification:

Product Details

■ Venus series large medium speed split reciprocating compressor, designed for high power and large pole load applications; can be driven by gas engine, steam turbine, motor.

Maintainability-The entire unit is designed for easy maintenance and all components are easily serviced.

■ Standardized-Most parts are standardized parts.

■ Pressure lubrication of the fuselage-the oil pump driven by the crankshaft provides lubricating oil pressure, and after cooling, it passes through the full-flow double-cylinder oil filter to supply oil to all moving parts in the fuselage. When required, a motor-driven high-pressure plunger pump forced oil injection system provides lubricating oil for the cylinder and packing. All pipelines of the lubrication system are made of stainless steel.

■ Unloading device-variable clearance cylinder, pneumatic suction valve unloading device and circuit adjustment mode are available.

■ Heavy-duty crankshaft-integral forged crankshaft through torsional vibration analysis to meet high-speed and smooth operation.

■ Heavy-duty body and crosshead slide-reinforced, heavy-duty body made of high-strength cast iron, with detachable steel top cover and end cover. Heavy-duty crosshead slide integrated with the fuselage, external reinforcement, removable side cover.

■ Precision bearings-precision split three-metal main bearings and connecting rod bearings.

■ Heavy-duty crosshead-long-life crosshead with detachable sliding shoe, fully lubricated to ensure minimum wear. Equipped with hardened steel crosshead pins.

■ Rigid connecting rod-high-strength alloy steel forgings, bolted connections, rolled threads, H-section.

■ Mature cylinder design-air-cooled/water-cooled cylinders, cancel the balance section, reduce internal leakage, improve the volumetric efficiency of the compressor, and reduce power consumption. Large channel intake and exhaust ports and large channel gas channel design, with special treatment of dry cylinder liner.

■ High-strength bolts-pressure-bearing parts are of grade 8.8 and above, and all bolts are easy to maintain.

High efficiency valve-low shear stress design, to solve the valve spring and valve plate stress and fatigue problems, to ensure that the rated conditions with extraordinary service life.

■ Durable piston-the piston body is usually made of wear-resistant cast iron or steel, the low-pressure large-diameter piston is made of aluminum piston, and the piston ring groove part is strengthened by nanotechnology.

■ Piston rod-according to the scientific flexibility than the design of the fine steel piston rod, the use of rolling thread, reduce stress concentration, prolong service life.

■ Skid-mounted design of the whole machine reduces the user's on-site installation workload and is easy to maintain.

Previous: Gas storage compressor unit

Next: None

Recommend Products

Consulting Quotation

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.