PRODUCT CENTER

Station-type LNG filling station

Based on the modular design concept, the site layout is flexible and changeable; ■ The pump tank adopts the upper cover insulation structure, and the BOG production is small;

The main equipment of pressure regulating skid includes: air-temperature gasifier (optional, gasification volume optional), gas filter, gas pressure regulator, turbine flowmeter, automatic odorizer and supporting pipelines, instruments and valves.

LNG filling skid is the core equipment of LNG filling station. Unloading/booster vaporizer, EAG heater, submersible pump, pump pool, remote control valve, pressure sensor and temperature sensor for automatic control are integrated on the skid.

LNG Integrated Filling Station System Solution

Special customization of the storage tank, breaking through the height difference limit between the liquid outlet of the storage tank and the pump pool;

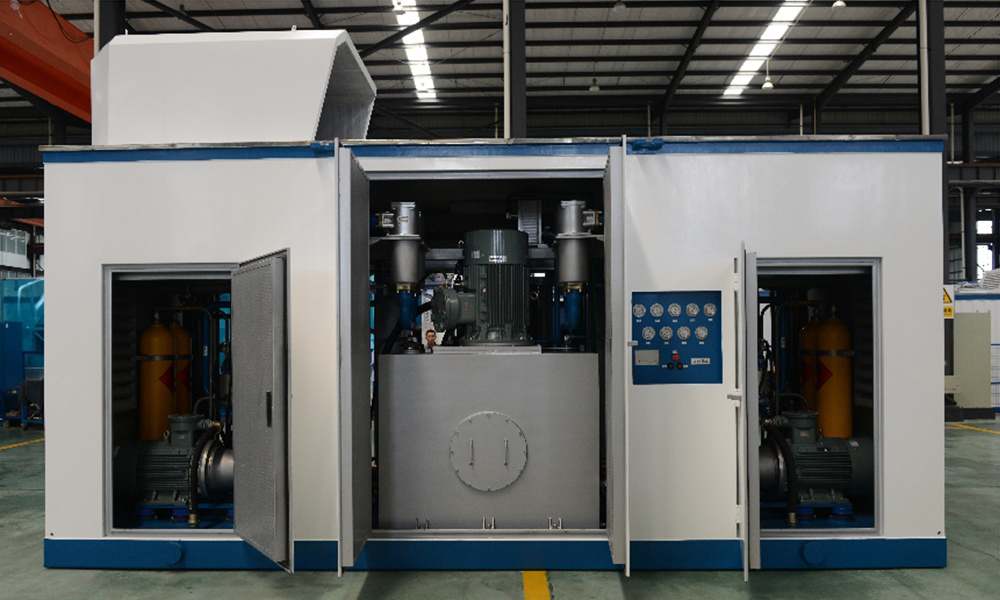

Hydraulic piston type CNG sub-station standard station double working mode compressor

The compressor system with dual gas source working mode, which integrates CNG sub-station mode and CNG standard station mode, can realize different mode gas filling functions of parent station gas source and pipeline gas source, and the two modes can be switched with one key.

CNG pre-dehydration unit refers to the equipment installed in front of the compressor, and the raw material pressure is the incoming pipeline pressure. It adopts the principle of temperature swing adsorption dehydration, uses the physical nature of the adsorbent to adsorb the saturated water in the raw natural gas in the incoming pipeline pressure state, and then uses the residual gas in the regeneration tower to carry out equal pressure, closed and zero emission analysis of the saturated adsorbent at a higher temperature. Adsorption and analysis are carried out in reverse.